AI/Big Data Construction Case_

Establishment br.mobof a heterogeneous mixing defect prevention system through machine vision data learning for automobile parts manufacturers

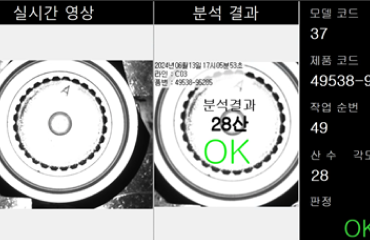

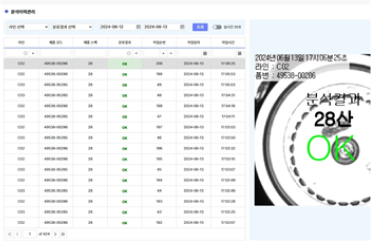

DL Information Technology Co., Ltd. has built and is currently operating a heterogeneous mixing defect prevention system through machine vision data learning for automobile parts manufacturers as a manufacturing data AI problem-solving solution demonstration project

Raw data

Analysis environment/Technology

Data collection/Loading

Visualization

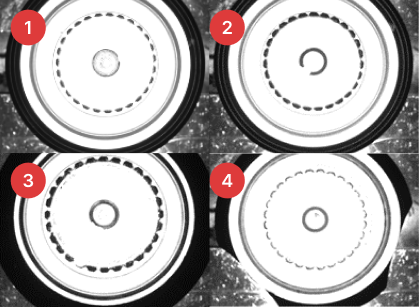

Raw Data

- 127 screw threads 30 degrees

- 227 screw threads 45 degrees

- 328 screw threads

- 431 screw threads

- H/Shaft top photo taken during manufacturing process (black and white)

- Image resolution: 5MP (2592 × 1944)

- Can be divided into 27 screw threads 30 degrees, 27 screw threads 45 degrees, 28 screw threads and 31 screw threads, and there are several types of products for each category

- Each product has a different height, which makes lighting and camera focus different

- A new product photo is collected every 30 seconds, resulting in about 1TB of original data

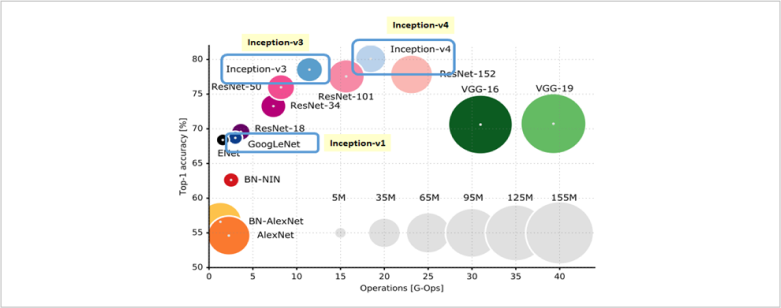

Analysis environment / technology

- Test ResNet, VGG, YOLO, Inception deep learning models and SVM machine learning models to select the optimal model

-

Characteristics of Inception V4 model

- Stabilizing deep neural network training by introducing Residual Connection

- Optimizing the existing Inception module to achieve high efficiency using fewer parameters and shortening learning and inference time

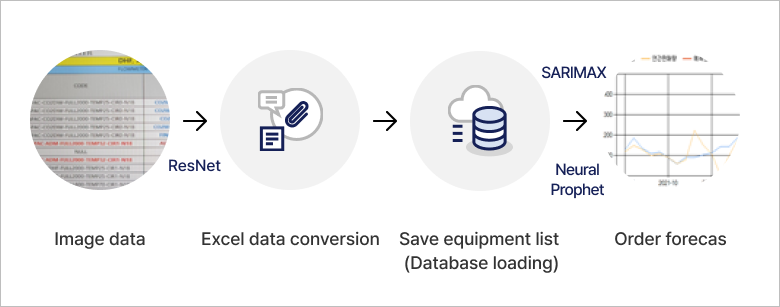

Data Collection / Loading

- When the product is located under the camera, PLC transmits a shooting signal to the PC connected to the camera

- Camera shooting

- Save the image as a work date_time_sequence_item number.bmp file

REFERENCE

REFERENCE

AI·Big Data

AI·Big Data