REFERENCE

REFERENCE

Smart Disaster Safety

Smart Disaster Safety

Based on over 20 years of experience in building smart factories,

DL Information Technology Co. Ltd. is creating manufacturing big data analysis

and AI application cases in various industrial fields

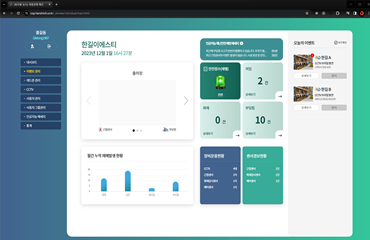

Through the 2023 Chungcheongbuk-do AI and Metaverse-based Industrial Safety Management System Reinforcement Project, DL Information Technology Co., Ltd. has completed construction and is operating an industrial disaster integrated control system for 10 Chungcheongbuk-do manufacturing companies together with a consortium

of 4 companies.

Real-time collection of IoT/UWB sensor data

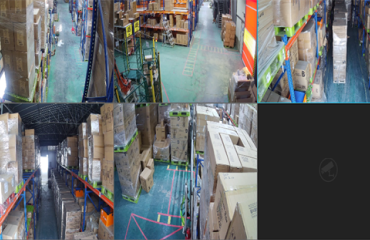

CCTV video analysis

Integrated disaster safety control

Individual disaster safety control

Safety management

self-diagnosis

required

Interest and

will required

Increase in new types

of safety accidents

Increase in need

for worker safety