REFERENCE

REFERENCE

AI·Big Data

AI·Big Data

Based on over 20 years of experience in building smart factories,

DL Information Technology Co. Ltd. is creating manufacturing big data analysis

and AI application cases in various industrial fields

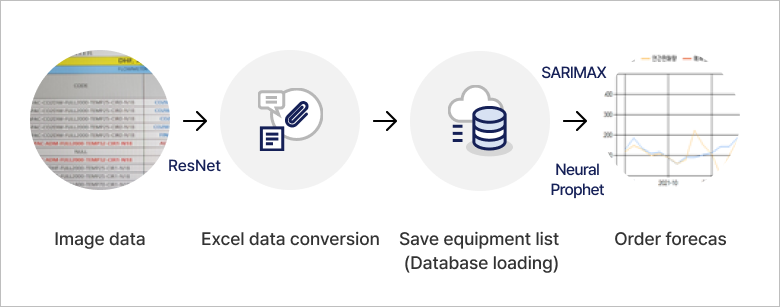

DL Information Technology Co., Ltd. provides intelligent raw/subsidiary materials purchase order demand forecast for Chungnam mobility enterprises through Chungnam AI regional specialized industry

Image order form

Public institution websites

Dataset

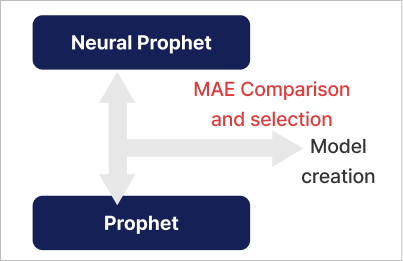

Learning and verification

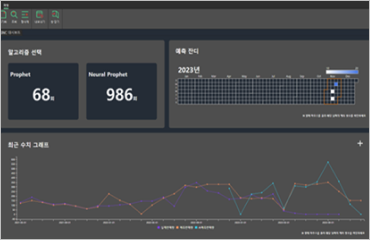

Forecast status dashboard screen

Demand forecast result screen

Manual method

Difficult to respond

Increase in

unnecessary

inventory

Ordering raw/subsidiary

materials,

quantity error