REFERENCE

REFERENCE

Manufacturing Digital Transformation

Manufacturing Digital Transformation

Based on over 20 years of experience in building smart factories,

DL Information Technology Co. Ltd. is creating manufacturing big data analysis

and AI application cases in various industrial fields

Complex document management

Low usability of data

Occurrence of

human errors

inefficient work processing

User-friendly POP program configuration

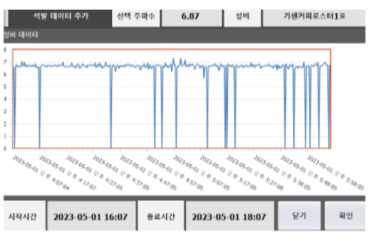

Data performance aggregation

Visualized dashboard chart configuration

Link with smart HACCP standards

Processed food

Beverage

manufacturing

Confectionery

and bakery

Agricultural and livestock

product processing

Refrigerated/Frozen

distribution