REFERENCE

REFERENCE

Manufacturing Digital Transformation

Manufacturing Digital Transformation

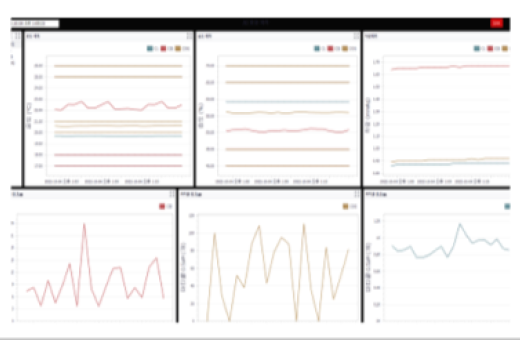

Based on over 20 years of experience in building smart factories,

DL Information Technology Co. Ltd. is creating manufacturing big data analysis

and AI application cases in various industrial fields

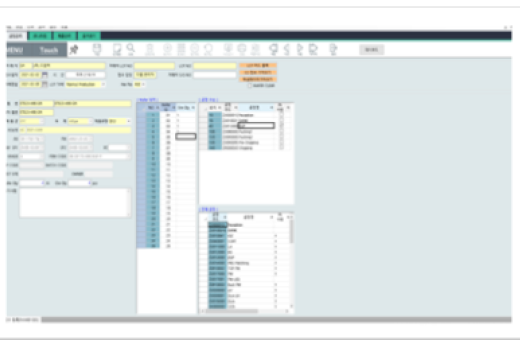

Inefficiency of

integrated

management

Insufficient process linkage

Insufficient document management system

Limited scope

Configuration of MES-ERP linkage functions

Implementation of the materials management process linked to process operations

Activation of SCM integration functions such as shipment and delivery

Activation of delivery management functions

linked to clients

Implementation of systems linked to the quality management system

Transportation

machinery

Electronics and

semiconductors

Pharmaceuticals

and bio

Food and beverages

Chemical products